※ Conveyor Belt

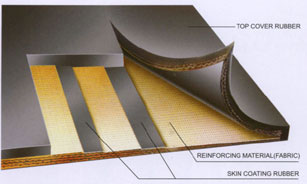

Quality polyester cotton fabric and high strength canvas as belt carcasses covered with different properties of rubber compounds ,normal and high strength of open end or endless belts of all kinds can be produced, such as heat resistant ,oil resistant ,acid &alkali resistant and cold resistant conveyor belts etc .

Features:

- Specifications and properties of covers exceed national standards and can follow international standards, such as DIN, BS, AS, JIS, SABS, IS etc.

- High adhesion of ply/ply, cover/ply and impact proof.

- High full belt strength, small elongation and reliable durability.

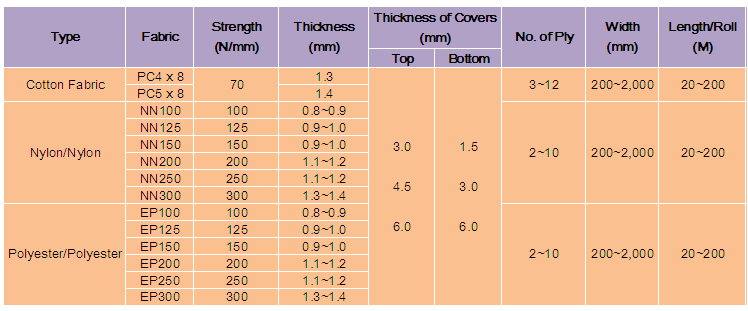

Type |

Standard, Property and Application |

Normal |

GB7984-2001

Full belt high strength, wear proof, suitable for mining, building and conveying power and lumps. |

Oil-Proof |

Q/LXS-012

Oil resistant, ozone resistant suitable for conveying oil-content materials. |

Cold Resistant |

HG/T 3647-1999

Surrounding temperature -45℃~+50℃, suitable for operation in cold areas. |

Acid & Alkali Proof |

Q/LXS-012

Ph value 5-9 acid & alkali materials, suitable for conveying fertilizer, wood pulp, acid & alkali materials. |

Heat Resistant |

HG2297 T1(≦100℃) ; T2 (≦125℃)

Suitable for cement, metallurgical industry, conveying high temperature materials. |

High Temperature Resistant |

HG2297 T3 (≦150℃)

Suitable for cement, metallurgical industry, conveying high temperature materials up-to 180℃ |

Cautions:

- Conveyor belts of different specifications and sizes should not be spliced together.

- Hot and cold splice are optimized.

- Belting selection must be strictly made as per conveyor designs and attention should be paid especially to diameters of drive pulley and return pulley. Starting with load is prohibited. Falling of materials into between belt and pulley should be avoided.

- Belts should be properly kept from sun irradiation, rain, snow and prevented from acid, oil, or other materials which may render belting to default. Belts should be stored 1 meter away from heat sources and in reels turned over at a interval of 3 months at an ambient temperature -10℃~+40℃.

Remarks: Belting out of the above specifications can also be made on requests. |

M2=Belt width(m)×[No.of ply +Top cover thickness (mm)+Bottom cover thickness(mm)] ×Belt length(m) |

|